WHY SEALING THE JOINTS OF A REFRIGERATION PANEL?

We have indicated that there are the following types of joints of refrigeration panel:

- Visible fixation joint or basic tongue and groove joint

- Concealed fixation joint

- Cold-room joint or labyrinth joint

- Hermetic joint

The detailed article about the types of joints for wall insulated panels is here.

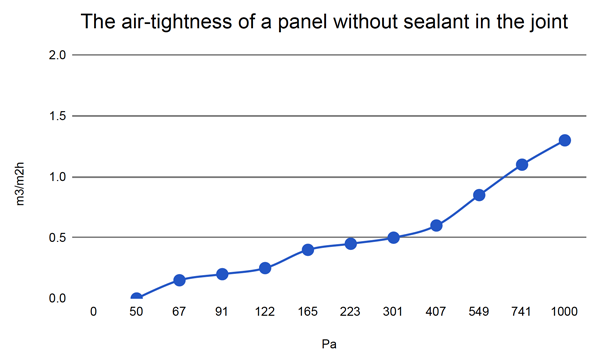

Graphic. The air-tightness of a panel without a sealed joint.

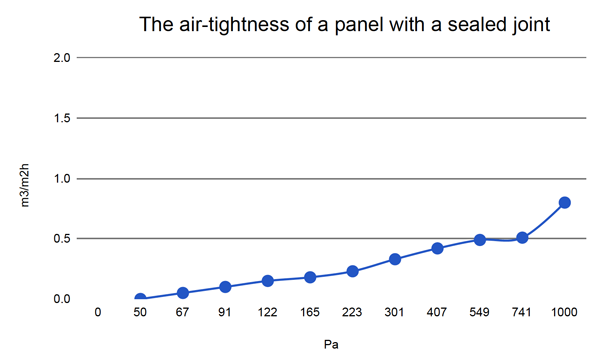

Graphic. The air-tightness of a panel with a sealed joint.

CONCLUSION

Before choosing the type of joint of the insulated panel and the type of sealant required please take into consideration the geographic area where the installation will take place, exposure to the sun, humidity, and rainfall. The most important, sealing joints is an essential element for a large installation.

CONTACT US

To learn more about the cold-room panels, you can get in touch on +44 7887 884768. You can also contact us via sales@globepanels.com or completing the contact form below. Once you reach out to us we can provide you with a free quote and can also discuss our products and services further.

WhatsApp Us

WhatsApp Us