The advantages of using PIR and PUR insulated panels in the construction of agro-industrial complexes. What does agro-industrial installation need? For sure, the high speed of development, low-cost, and trouble-free operation for at least 20 years.

Contemporary market conditions impose specific requirements for the energy efficiency of such structures. Since the majority of heat or cool loss occurs through the building envelope, it contributes directly to increase energy costs. It, in turn, leads to higher costs of production.

Fruit and vegetable storage has strict requirements for temperature and humidity level. For example, potatoes, eggplant, cucumbers, tomatoes, and peppers stored at a temperature from 0 to + 8 °C. And this temperature regime should be continuously maintained all the time.

To prevent spoilage of products, it is necessary to build sealed greenhouses, with a controlled or modified atmosphere with low oxygen content. It increases the refrigerated life of products from 2-3 to 6-8 months.

Also, the final cost of products is influenced by initial production costs. To cut costs, reduce the building material of the construction. Therefore, agricultural buildings should be build from a lightweight and durable material having a low coefficient of thermal conductivity.

The speed of construction is influenced by atmospheric phenomena — rain, snow, and so-called “human factor”. Consequently, the material used to build a vegetable store, or an animal farm, must be waterproof and all-weather, and all the processes simple and straightforward for installers.

The advantages of the construction of vegetable storage facilities and construction of agro-industrial complex of PIR and PUR insulated sandwich panels.

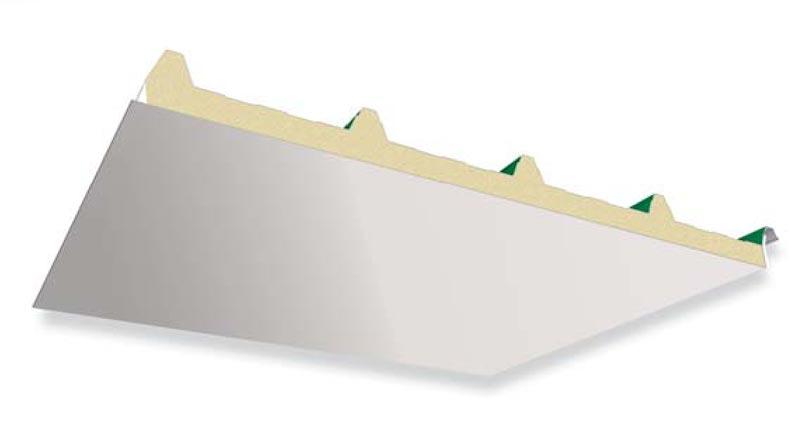

The sandwich panel consists of three layers: external metal support, the insulation layer, internal metal support.

PIR is a type of flame retardant polyurethane foams, where the so-called thermosetting polymer is a polyisocyanurate. Under high temperatures, it prevents the spread of flames. Therefore, using PIR panels, you can erect structures with particularly stringent requirements for fire resistance.

Insulated sandwich panels made of polyurethane foam can be used to build in the shortest possible time fruit storage, a cold room, or a processing plant. The resistance of polyurethane foam to moisture allows you to install it, regardless of the time of year.

Due to lower weight, PIR panels are more comfortable to manipulate at the construction site.

The processing of meat, fish, vegetables, and fruit must be executed in the cleanest environment possible. Sandwich panels are moisture-resistant: they are chemically inert and biologically stable. They do not decay with time. They can resist acid and alkaline environments. It does not rot and is not susceptible to the harmful effects of rodents and insects.

The most crucial advantage of PUR foam sandwich panels is the hermetic joint, which does not require any further connector for assembling.

Summing up

Considering technological and installation factors, PIR and PUR insulated sandwich panels have no competitors. Using PUR insulated panels significantly speeds the construction of agricultural complexes up. Insulated panels have a long life, are easy to install, and allow to build any agro-industrial structure, which in the future will not require repair and, therefore, the use of insulated panels reduces all the operating costs in the long term.

Agriculture and farming may create aggressive environments, we can advise you on the best solution for your specific need; insulation made by PIR or PUR foam, ranging from 25 to 240mm of insulating thickness The standard coating on the external side are Polyesthere or Plastisol or HPS200, on the internal side we recommend aluminum or fiberglass reinforced fiber.

Our panels can be used for a wide variety of industrial use, providing easy installation of walls and roofs — insulation made by PIR or PUR foam, ranging from 25mm to 160mm of insulating thickness. The standard coating is Polyester, we as well can also provide PVDF and PET coatings.

Nos panneaux peuvent être utilisés après une installation facile comme murs ou revêtements pour une variété d’utilisations industrielles. Isolation PIR ou isolation de mousse de polyuréthane avec une variation d’épaisseur de 25mm à 160mm d’isolation. La finition standard est le Polyesthere et les revêtements en PVDF et en PET sont également disponibles.

WhatsApp Us

WhatsApp Us

0 Comments Laisser un commentaire