Product Description

PRE-INSULATED DUCT SYSTEM FOR CIVIL, INDUSTRIAL, AND COMMERCIAL BUILDINGS.

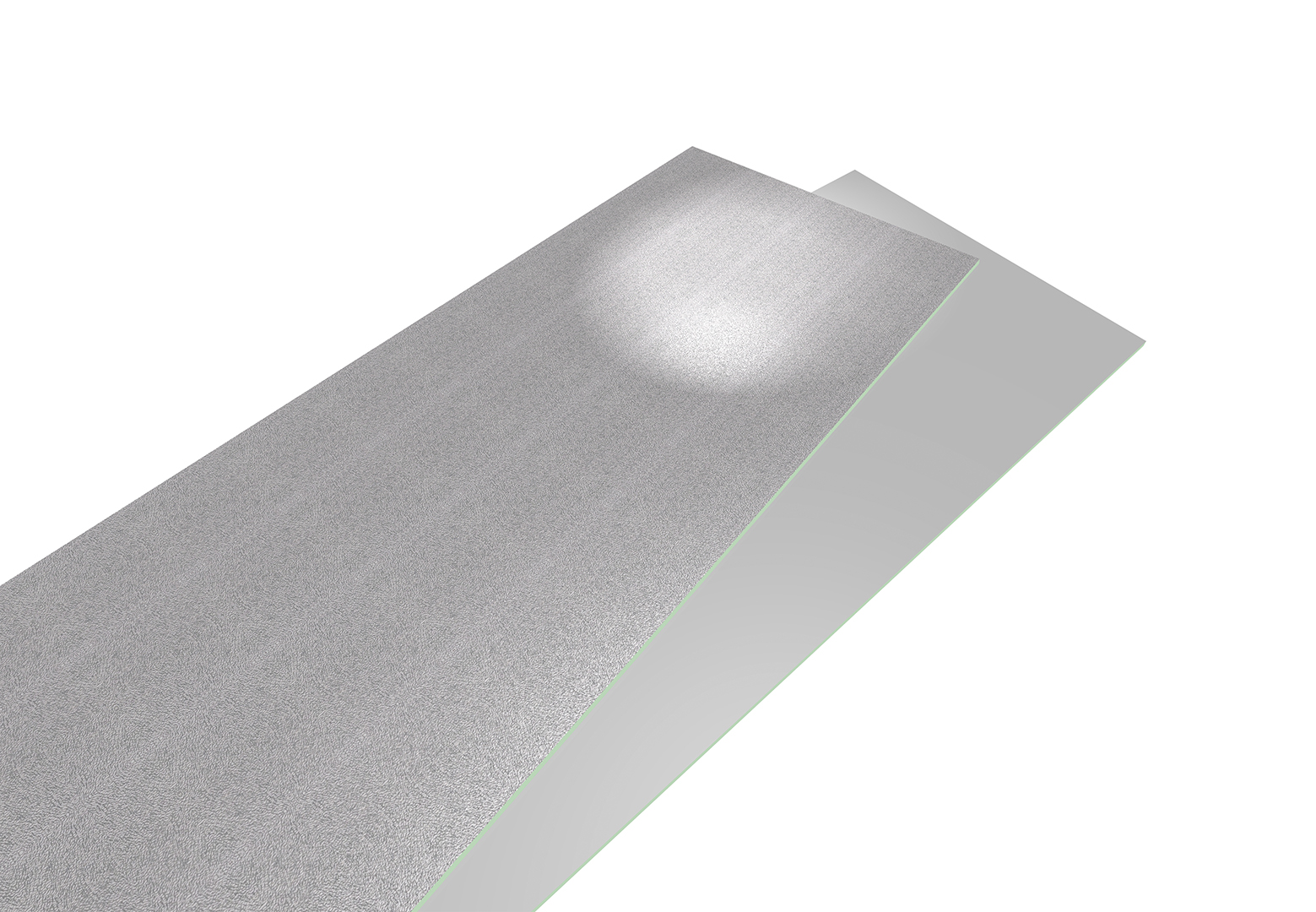

High-performance insulation board manufactured from CFC or HCFC free closed-cell rigid polyisocyanurate PIR foam. It’s covered on both sides with a 60 μm embossed aluminum foil. For internal use in residential/commercial and industrial buildings

Density of the foam: 35 ± 3.0 kg/m3

Dimensions: width and length 1200 x 4000 mm

Thickness: 20,5 mm and 30,5 mm

Main application: for the construction of pre-insulated aluminum ducts for air distribution

Main characteristics and performance:

- Insulating material density – ρ [kg/m3 ] EN 1602 – average value 35 ± 3.0

- Average thermal conductivity: λ9090, I [W/mK] EN 13165 Annex A and C Value determined 10° C 0.021

- Resistance against pressure: EN 13403. The duct resists at the maximum pressure of 3750 Pa

- Air leakage classification: EN 13403, EN 1507. Globe duct constructed using bayonet profiles is in B class

- European fire reaction: Globe duct EN 13501-1, EN 11925-2, EN 13823 B s1 d0 – 20 and 30 mm

- British fire reaction class: Globe board BS476: part 6:1989, 0 Class, BS476: part 7:1997, 1 Class, BS476: part 6/7, 0 Class

- Smoke toxicity: British Naval Engineering Standard NES 713 < 4.5

- Release of dangerous substances: ISO 16000-9, ISO 16000-6 Available on request

- Duct Dimensions 200 x 200 1 m Duct Dimensions 400 x 400 1 m Duct Dimensions 600 x 600 1 m Frequency Hz dB dB dB

- Rigidity class: EN 13403, 160.000 (R3)

- Acoustic experimental values: dB EN ISO 7235; Insertion loss in octave band

- Blowing agent EN 15804 OPD (ozone depletion potential) = 0 and GWP (global warming potential) does not include in CML; IA:2016

- Tolerance [mm]: EN 13165; width and length ± 7,5 for 1200 mm; ± 10 for 4000 mm; thickness ± 0,7 mm

- Stability to the temperature: Globe panels are used in a range of continuous temperatures normally included between -40° C and +110° C. Long exposures to the temperatures could cause deformations to the foam or to the coats, but without causing sublimation or fusion.

- Aspect: prolonged exposure of the polyurethane foam to UV rays can cause surface oxidation, the phenomenon does not affect the basic characteristics and performance of the panel.

DOWNLOAD TECHNICAL CHARACTERISTIC

GET IN TOUCH WITH US

If you have any questions about the pre-insulated duct system, please contact us and we will gladly answer them. You may reach us at +44 7887 884768 or by filling out the form below. You may also reach out to us at sales@globepanels.com. When you contact us, we can give you a quotation and further discuss our goods and services.

WhatsApp Us

WhatsApp Us